Stock Count Cheat Sheet

- May 6, 2025

- 2 min read

Updated: May 13, 2025

How to Product-wise Stock Count and Storage-wise Stock Count in Material Management Application

Goal 1: Storage-wise Stock Count

Pause All Material Operations for the Storage Location - Send a message to all relevant teams informing them that all material operations for the specific storage location need to be paused temporarily for an inventory count.

Assign a Stock Count for the Location/Storage - Manager raises a Stock Count Request for the Storage/Location to be Counted 💻

a. Using Create New

b. Using Bulk Upload

Download Storage-wise Stock Balance - Used as reference for verification during Stock Count 💻

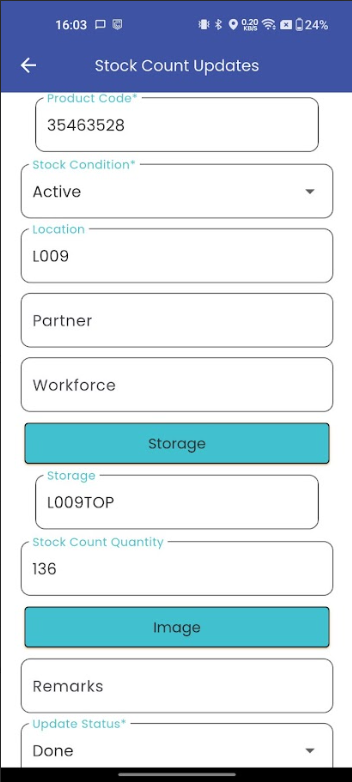

Share Stock Count Updates - The Field User (or whoever is doing the Stock Count physically on the floor) shares a Count update through the Android/iOS App against the count activity (with image capture) by verifying against the downloaded report 📱

Review Errors - Managers should regularly review errors in order to make sure no data is missed. This should be done from oldest to newest to prevent issues in stock transactions.

Goal 2: Product-wise Stock Count

Pause all Material Operations for the Product - Send a message to all relevant teams informing them that all material operations for the specific product need to be paused temporarily for an inventory count.

Assign a Stock Count Activity for the Product - Manager raises a Stock Count Request for the Product to be Counted 💻

a. Using Create New (or)

b. Using Bulk Upload

Download Storage-wise Stock Balance of the Product - Used as reference for verification during Stock Count 💻

Share Stock Count Updates - The Field User shares a Count update through the Android/iOS App against the count activity (with image capture) by verifying against the downloaded report 📱

Review Errors -Managers should regularly review errors in order to make sure no data is missed. This should be done from oldest to newest to prevent issues in stock transactions.